In our previous post, we'd studied the helical magazine, as invented by Calico Inc. in 1985. However, there is a precusor to this that was invented in the 19th century, called the Evans Repeating Rifle, that also used a helical magazine of sorts. We will study that particular rifle in today's post.

The Evans rifle was invented by Warren R. Evans, a dentist from the state of Maine. He received his first patent for an improved magazine in December 1868 and another patent for an improved gun lock in 1871. With these two patents, he entered his prototype rifle into the US Army trials of 1872, but his rifle was not selected due to mechanical issues. However, he wasn't the only mechanically inclined person in his family and his brother, George Franklin Evans, was also a talented machinist. He and his brother joined forces with a few other investors and started the Evans Rifle Manufacturing Company in Maine in 1873, to manufacture this rifle design for the commercial market.

The Evans rifle was invented by Warren R. Evans, a dentist from the state of Maine. He received his first patent for an improved magazine in December 1868 and another patent for an improved gun lock in 1871. With these two patents, he entered his prototype rifle into the US Army trials of 1872, but his rifle was not selected due to mechanical issues. However, he wasn't the only mechanically inclined person in his family and his brother, George Franklin Evans, was also a talented machinist. He and his brother joined forces with a few other investors and started the Evans Rifle Manufacturing Company in Maine in 1873, to manufacture this rifle design for the commercial market.

An Evans Repeating Rifle

This rifle is a lever-action firearm and the trigger guard doubles as the lever that operates the action. Like the Spencer rifle (which we studied earlier here and here), this rifle also has a magazine inside the stock. However, the Spencer rifle has a tubular stock, whereas this rifle has a helical type feed mechanism that uses an Archimedian screw (The screw gets its name from the fact that it was supposedly invented by Archimedes, but was actually invented by Assyrians about 350 years earlier. It was used for pumping water in the ancient world). In the case of the Evans rifle, the screw thread is used to push cartridges into the chamber.

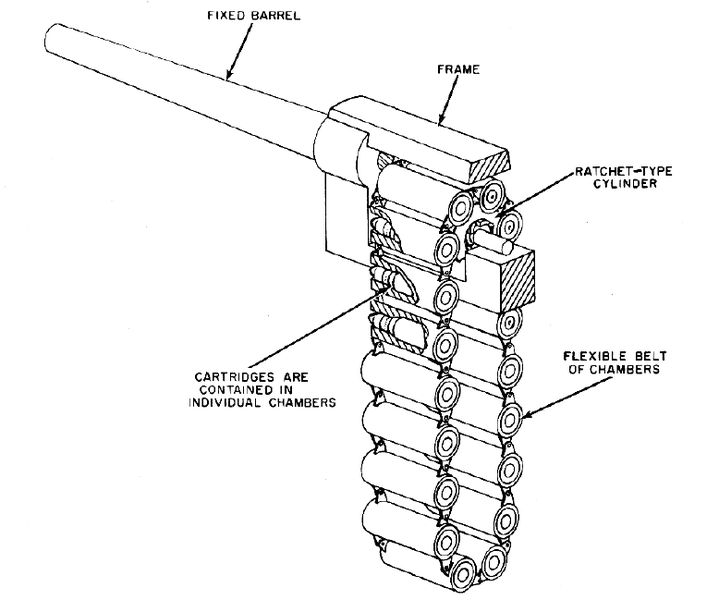

Disassembled Evans Rifle Magazine.

The above image shows a disassembled Evans rifle magazine. The barrel is facing to the left and the two halves of the magazine occupy most of the picture. The screw thread can be clearly seen inside the magazine. Unlike the helical magazine that we studied in the previous post, this one is not spring loaded. Instead, upon operating the trigger guard lever, the screw rotates 1/4th of a turn, which pushes the next cartridge into the chamber.

Like the Spencer rifle, new cartridges are pushed in from the base of the buttstock. Unlike the Spencer rifle's tubular magazine, this is safe to use with centerfire cartridges using spitzer type bullets because the tip of each bullet does not touch the primer of the previous cartridge. The Evans rifle holds 34 cartridges in its magazine, compared to the Spencer's seven cartridge tubular magazine and the Winchester M1873, which holds 15 cartridges in its tubular magazine.

About 12000 to 15000 rifles were manufactured by the company during its existence. Evans rifles were given to several foreign military officers and politicians and were also endorsed by celebrities of the day, such as Kit Carson and Buffalo Bill Cody. In fact, Kit Carson even enthusiastically submitted the following testimonial to the Evans company, saying: "At twenty paces, have, with this rifle, shot the eyebrows from my wife, and every night regularly, in the presence of an audience I shot an apple from her hand, a pipe from her mouth, a penny from her fingers, or snuff a candle from her hand. I think the Evans is the safest and most complete repeating system ever devised."

An enthusiastic endorser of the Evans rifle. An Apache Indian holding an Evans rifle from around 1880. Public domain image.

However, there are a few disadvantages of this design as well:

The first is that the new cartridges are loaded through the butt plate, not the front of the magazine (unlike the Calico helical magazine that we studied in the previous article). This means that if the user loads a single cartridge into the magazine, he (or she) has to pull the lever 33 times so that the cartridge works its way through the magazine into the chamber.

Another issue is that the lever controls both the feeding and loading of the magazine at the same time. This presents problems when trying to refill a partially filled magazine On other firearms, such as the Winchester M1873 with a tubular magazine, or the Calico submachine gun, the magazine feed is independent of the action. Therefore, if the user fires (say) three cartridges, the user can then simply push in three more cartridges and top off the magazine. On the Evans rifle, if the user has a fully loaded rifle, then fires three cartridges and then wants to top off the magazine, the user must pull the lever each time a new cartridge is pushed through the butt plate to load the magazine. This means that loading three cartridges through the butt plate will eject three more cartridges from the top of the magazine and there will be a gap in the magazine before the last three cartridges can be fired. The only way that a user can always keep the magazine topped off is by firing a single cartridge, then pushing a new cartridge into the butt plate and operating the lever to eject the old cartridge case and load the new cartridge into the magazine. This problem was later partially solved by George Evans in 1877, by making a design modification that allowed the user to load the rifle from from the breech end, without disturbing the cartridges already in the magazine.

This rifle also uses specially designed cartridges (the .44 Evans Short and .44 Evans Long for later models), which were not used by any other firearms and were not easily available either. The only manufacturer of this ammunition was the Evans Rifle Manufacturing Company themselves and they did not manufacture this ammunition in enough quantities to meet the market demands. The rifle also had mechanical issues and was affected by dust as well. These were some of the reasons why it was not to be accepted by the US Army in 1872. The company tried to enter the commercial market, but the lack of availability of ammunition for it caused it to not sell well. Also, after the Civil War (1861-1865), there was a surplus of firearms available on the market for cheap and the company could not compete on price against older established firearms companies. By 1879, the company went bankrupt and its assets were sold by March 1881.

The first is that the new cartridges are loaded through the butt plate, not the front of the magazine (unlike the Calico helical magazine that we studied in the previous article). This means that if the user loads a single cartridge into the magazine, he (or she) has to pull the lever 33 times so that the cartridge works its way through the magazine into the chamber.

Another issue is that the lever controls both the feeding and loading of the magazine at the same time. This presents problems when trying to refill a partially filled magazine On other firearms, such as the Winchester M1873 with a tubular magazine, or the Calico submachine gun, the magazine feed is independent of the action. Therefore, if the user fires (say) three cartridges, the user can then simply push in three more cartridges and top off the magazine. On the Evans rifle, if the user has a fully loaded rifle, then fires three cartridges and then wants to top off the magazine, the user must pull the lever each time a new cartridge is pushed through the butt plate to load the magazine. This means that loading three cartridges through the butt plate will eject three more cartridges from the top of the magazine and there will be a gap in the magazine before the last three cartridges can be fired. The only way that a user can always keep the magazine topped off is by firing a single cartridge, then pushing a new cartridge into the butt plate and operating the lever to eject the old cartridge case and load the new cartridge into the magazine. This problem was later partially solved by George Evans in 1877, by making a design modification that allowed the user to load the rifle from from the breech end, without disturbing the cartridges already in the magazine.

This rifle also uses specially designed cartridges (the .44 Evans Short and .44 Evans Long for later models), which were not used by any other firearms and were not easily available either. The only manufacturer of this ammunition was the Evans Rifle Manufacturing Company themselves and they did not manufacture this ammunition in enough quantities to meet the market demands. The rifle also had mechanical issues and was affected by dust as well. These were some of the reasons why it was not to be accepted by the US Army in 1872. The company tried to enter the commercial market, but the lack of availability of ammunition for it caused it to not sell well. Also, after the Civil War (1861-1865), there was a surplus of firearms available on the market for cheap and the company could not compete on price against older established firearms companies. By 1879, the company went bankrupt and its assets were sold by March 1881.